Recently, I've decide to give wooden molding planes a try and make my own set of hollows and rounds. After watching two DVDs on the subject, I was able to have pretty good success!

As you can see in the pics below, I started with the #18 hollow and round planes. I will continue on down to the #2's as time permits. These are time consuming at first to make but with the learning curve they begin to get done faster.

In this picture, you can see how the steel blade is shaped like a flag. The wedge is made from the waste after cutting the step out.

Here I used a piece of scrap to practice making the hollow plane with the round plane. Its looking pretty good so far. Once I plane the sole of the plane, they will be an exact match of each other.

They look pretty good for a first attempt!

Thanks for visiting, please leave comments etc...

Friday, May 30, 2014

Wednesday, December 14, 2011

The last masking tape you'll ever use...

I was recently commissioned to paint black & white strips on one of my crowns. I know, the paint will bleed and it will look horrible, best to just pass on the sale. Well, I figured nothing ventured nothing gained, so I agreed to paint the crown.

I heard about Frog Tape a few years ago while watching one of the DIY channels that covered the New Tool convention in Vegas. (Yes, tape is a tool! Haven't you heard of duct tape?) I never had a chance to actually try it out until now.

Wow! Sums it up. It may cost a little more but worth every penny! Well, see for yourself...

...not a single bleed, anywhere! The tape does exactly what the manufacturer states!

I'll never buy another brand of masking tape, ever.

I heard about Frog Tape a few years ago while watching one of the DIY channels that covered the New Tool convention in Vegas. (Yes, tape is a tool! Haven't you heard of duct tape?) I never had a chance to actually try it out until now.

Wow! Sums it up. It may cost a little more but worth every penny! Well, see for yourself...

...not a single bleed, anywhere! The tape does exactly what the manufacturer states!

I'll never buy another brand of masking tape, ever.

Tuesday, September 6, 2011

Half Round Bed Crown

Hi, I'm back! This time I'm going to step you through a half round bed crown. This crown was a custom order, so I had to make a jig to cut the top and bottom. Since it will be covered with fabric, I will not have to paint it...wahoo!

Let's get started...

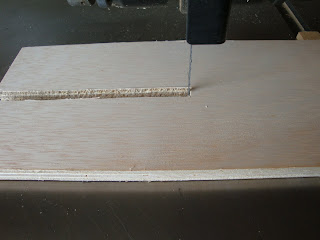

First off, I need to make a jig to get the perfect half round for the top and bottom. Cutting large circles is best performed on the band saw. Below you can see the miter gauge bar and a piece of 1/2 plywood I'm going to use for the base of the jig. I cut the dado so that the bar will fit snug, no play. Then I glue it to the base. The slot was cut using a hand saw.

Let's get started...

First off, I need to make a jig to get the perfect half round for the top and bottom. Cutting large circles is best performed on the band saw. Below you can see the miter gauge bar and a piece of 1/2 plywood I'm going to use for the base of the jig. I cut the dado so that the bar will fit snug, no play. Then I glue it to the base. The slot was cut using a hand saw.

The base is now set in place on the band saw. Now you can see why the slot needed to be so long. The base acts as a support for the turn table (you'll see in a minute). The band saw blade is just touching the jig base.

The view of the base as it sits in the miter gauge slot. Its a very snug fit, you don't want the jig to move.

I need to find the spot where the tooth will contact the wood. So I am using a square and a ruler to get my center line on the jig.

Here I am using the blank for the top to find the pivot hole for the turntable. I place slight pressure on the blade, since the mark on the top is offset about 1/16" from the edge. Notice there is a center line on the blank.

I align all of the center lines and mark the intersection. This should be the location for the pivot point. (I say "should" because some times thing don't go as planned.)

Its very important to use a brad point drill bit on a drill press to make the hole for the pivot point. You want to make sure you get the hole as close as humanly possible. The brad point will prevent the wood or bit to travel away from the mark.

Hmm, what was I just saying?? Well, I'll try it out, it's a little off. Maybe its time for a new pair of glasses?

For the pivot stud I used 1/8" plastic bars I had laying around. Then cut it to length after inserting it into the pivot hole. Leave a good 3/16".

I just used a sharp chisel to cut the excess off.

Here you can see the base and the turn table. The theory is if everything is centered than everything should line up. X marks the spot, basically where the two diagonals intercept marks center. I drilled the same size hole to accept the pivot point.

And she spins!

I pin nailed the blank onto to turn table and checked the alignment. Hmm, not looking too good, what was I saying before?? The blank is set too far away from the blade.

A slight problem, but easily fixed. I drill a 3/4 hole half way into the plywood turn table and patch it with a 3/4 dowel. Why 3/4? Well, that's what I had handy. You can use any size, just as long as its bigger than the original hole.

Once the glue sets up, I plane it flush. Ready for a new hole!

I extended the setup lines and drilled another hole.

Its looking good! One side lines up!

Ahh, now that's nice, the other side lines up too! Ready to make the cut.

And here is one cut to size. Looks really good, clean edge too, no sanding required. Those are always good words to hear, no sanding!

Instead of setting up the matching part, I'll just use this one as a template. So, I mark another blank.

I use a router with a flush trim bit and before you know it I have the top and bottom done with an extra for next time.

I cut a groove along the back of the top and bottom with a dado blade to hold the back in place. I also test fit a nailer.

The rod supports will extend the length of the frame, so I notched out three holes for the rod supports.

The rod supports have to follow the curve of the face, so I planed a slight curve in each.

All three dry fit nicely!

To cut the blank for the face, I used a couple of 2x4's stretched between my benches.

I use a fence that was made for this circular saw. I just line up the fence with the line and cut.

As you can see both pieces are supported which makes for a safe and clean cut!

I screw the top and the bottom to the back.

And I start to glue and screw the nailers.

The nailers are 5 inches apart, I use my bendable ruler to mark the locations.

With the nailers in place, I make sure the center nailer is square.

The frame is complete...

The face is cut to size and clamped in place. I mark the screw holes, 5 inches apart!

The rod support setup...

The center support...

Front view...

Side view...

Not a bad looking crown, needs batting and fabric and its good to go!

Friday, April 1, 2011

Mahogany Coffee Table

Hi, I'm back with another refinishing project. This time I refinished a mahogany coffee table top I designed and built 7 or 8 years ago. I originally finished it with Tried and True Varnish Oil. It looked great for a while but then it began to loose its luster. I guess from the abuse, I mean use, it endured through the years.

This time around I'm going to use boiled linseed oil, shellac, and wax to finish the top. It going to look great and might last longer than 7 yrs and I have a short video at the end (wahoo!)...

First off, I sand down to the bare wood, I sure there might be some varnish left behind from the last application but it'll be minimal and will not affect the new finish. The picture below it how the top looks before any treatment. As you can see, its looking kind of sad... :(

After a good sanding with 100 grit sandpaper, using my Festool Rotex set on the aggressive mode, it looks like this... (Notice there's no dust?? Not a photo trick, the picture was taken right after I finished sanding. The dust extractor is that good!!)

The first coat is a thin layer of boiled linseed oil. Apply just enough to spread the oil evenly across the wood. Then after a few minutes, wipe off the excess. Most of the oil will penetrate the surface. The picture below is how it looks wet...

After 24 hrs, the top looks like this...

Now for the next phase, I start applying the shellac. I'm using the unwaxed premix in the can, its just a little easier to get started with. The finish will look just as good if you mixed your own using the shellac flakes and alcohol.The pros like to adjust the ratio of alcohol to shellac for climate etc. The alcohol evaporates either way! Here's how it looks with the first coat of shellac...

After 24 hrs and before I sand with 400 grit paper, the top still needs work...

Ok, so now the shellac process begins. I sand with 400 grit with the grain, a light sanding, we just need a tooth for the next coat of shellac to adhere to. (Hmm, look at all that dust. If only I could attach my dust extractor to my sandpaper...)

So, lets get rid of the dust, I use a dry tack cloth to remove as much of the dust as I can...

I apply the second coat of shellac and wait 24 hours.

Here's how it looks the next day...

So, now I sand, again...

After the last sanding, its starting to look good, its beginning to have an even shine.

I apply the third coat of shellac...

Now that you get the idea, shellac, sand, shellac, sand... I'll speed it up a bit. Below is the fourth coat...

I apply the fifth coat of shellac...

I apply the sixth coat of shellac... The more coats you apply the deeper the finish will be!

Ok, now for a video, short but gets the point across... The top now shines nice. But wait, we're not done! The next phase it to apply wax to the surface. Its the same process as the shellac process. Sand, wax, sand, wax, sand, wax. I like to wax until the entire surface is even, usually takes three coats. But just like shellac, the more coats the deeper the finish will appear! (Wax on, wax off).

Hope you liked this post, feel free to leave comments or suggestions!

Subscribe to:

Posts (Atom)